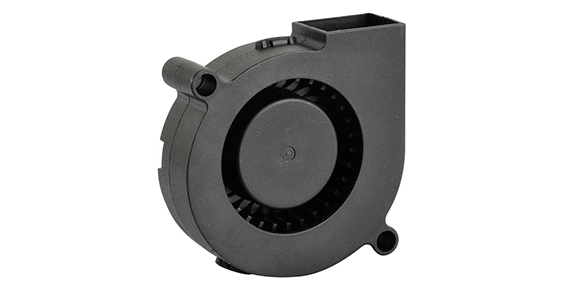

A 120mm DC blower fan is a type of cooling fan that is commonly used in electronic devices such as personal computers, servers, and gaming consoles. It is designed to move a high volume of air at a moderate pressure, thereby providing efficient cooling for the devices. The 120mm size is popular due to being compatible with many electronic devices while still being relatively small. These fans have a compact design and low noise operation. They are also energy-efficient, making them a cost-effective and environmentally friendly cooling solution. Overall, the 120mm DC blower fan is a reliable and effective cooling option for various electronic devices.

Types of 120mm DC Blower Fan

EN

EN

+

+

+

+

+

+

+

+