When it comes to electronics cooling and ventilation systems, 40mm blower fans play a crucial role. These small but powerful fans are commonly used in various electronic devices to ensure proper airflow and prevent overheating. In this article, we will explore the common uses of 40mm blower fans and discuss important factors to consider when selecting one for specific applications. We will also delve into the advancements in 40mm blower fan technology, highlighting improved efficiency and performance. Lastly, we will provide maintenance and care tips to ensure optimal performance of these fans.

Understanding the working principle of 4010 blower fan

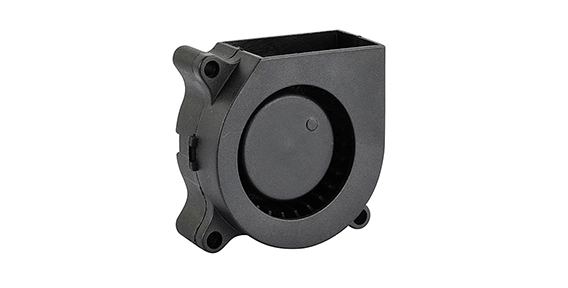

Before we delve into the common uses of 40mm blower fans, let's first understand their working principle. A 40mm blower fan operates on a 24v power supply and utilizes a centrifugal design to produce airflow. These fans consist of a motor, impeller, and housing. The motor converts electrical energy into rotational energy, which drives the impeller to rotate at high speeds. As the impeller spins, it draws in air from the surroundings and expels it through the exhaust ports on the housing. This continuous airflow helps to dissipate heat and maintain optimal temperatures in electronic devices.

Advancements in 4010 blower fan technology: improved efficiency and performance

Over the years, advancements in 40mm blower technology have led to improved efficiency and performance. Manufacturers have focused on developing more efficient motors and impellers, resulting in increased airflow and reduced energy consumption. Additionally, the use of advanced materials and aerodynamic designs has contributed to quieter operation and improved reliability. Some 40mm blower fans also incorporate features like PWM (Pulse Width Modulation) control, allowing for precise fan speed adjustment based on temperature requirements. These advancements ensure that electronic devices remain cool and perform at their best.

Factors to consider when selecting a 4010 blower fan for specific applications

When selecting a 4010 blower fan for specific applications, several factors should be considered. First, it is crucial to determine the airflow requirements of the electronic device to ensure that the fan can provide adequate cooling. The static pressure capability of the fan should also be taken into account, as it determines how well the fan can overcome any resistance in the system. Additionally, noise levels, power consumption, and reliability should be considered when selecting a blower fan. It is important to choose a fan that meets the specific requirements of the electronic device to ensure optimal performance.

Maintenance and care tips for ensuring optimal performance of 4010 blower fan

To ensure optimal performance and longevity of a 4010 blower fan, regular maintenance and proper care are necessary. It is important to keep the fan and its surroundings clean to prevent the accumulation of dust and debris, which can hinder airflow and cause the fan to work harder. Regularly inspecting the fan for any signs of damage or wear and tear is also essential. If any issues are detected, timely repairs or replacements should be made. Additionally, following the manufacturer's guidelines for lubrication and usage can help prolong the lifespan of the fan.

In conclusion, 4010 blower fans are widely used in electronics cooling and ventilation systems to ensure proper airflow and prevent overheating. The working principle of these fans involves the conversion of electrical energy into rotational energy to produce airflow. Advancements in 40mm blower fan technology have led to improved efficiency and performance, with features like PWM control and advanced designs. When selecting a blower fan, factors such as airflow requirements, static pressure capability, noise levels, power consumption, and reliability should be considered. Regular maintenance and care are crucial for ensuring optimal performance and longevity of these fans.

EN

EN

+

+

+

+

+

+