The Role of Predictive Analytics in Centrifugal Blower Fan Maintenance

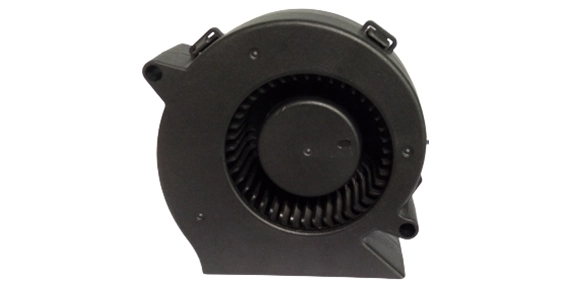

Centrifugal blower fans play a crucial role in various industrial applications. They are used to create airflow and provide ventilation in manufacturing facilities, power plants, and other large-scale operations. To ensure the efficient and reliable performance of these fans, regular maintenance is essential. However, traditional maintenance practices can be time-consuming and costly.

In recent years, predictive maintenance has emerged as a groundbreaking approach to equipment maintenance. By utilizing advanced analytics and real-time monitoring, predictive maintenance allows for the early detection of potential issues, reducing downtime and optimizing performance. This article will explore the role of predictive analytics in centrifugal blower fan maintenance and the benefits it offers.

Understanding the Essentials of Predictive Maintenance for Centrifugal Blower Fans

Predictive maintenance is a proactive approach that leverages data and analytics to anticipate equipment failure and schedule maintenance activities accordingly. When it comes to centrifugal blower fans, predictive maintenance involves continuously monitoring various parameters to detect any deviations from normal functioning. These parameters can include vibration levels, temperature, motor current, and fan speed.

By monitoring these metrics in real-time, maintenance teams can identify early warning signs of potential problems before they escalate into major failures. For example, an abnormal increase in temperature or vibration levels might indicate bearing wear or misalignment. With predictive analytics, maintenance personnel can receive automatic alerts when predefined thresholds are exceeded, allowing them to take corrective action promptly.

Real-Time Health Checks: Continuous Monitoring for Predictive Maintenance in Centrifugal Blower Fans

Continuous monitoring is a crucial aspect of predictive maintenance for centrifugal blower fans. By installing sensors and IoT-enabled devices, maintenance teams can collect real-time data on fan performance. This data is then analyzed using advanced algorithms to detect patterns and anomalies that might signify potential issues.

Real-time health checks enable maintenance personnel to make data-driven decisions and prioritize resources effectively. Instead of relying on periodic maintenance schedules or reactive repairs, continuous monitoring allows for ongoing assessment of the fan's condition. This proactive approach reduces the risk of unexpected failures and extends the fan's lifespan, resulting in significant cost savings for businesses.

Centrifugal Blower Fan: A Case Study

To illustrate the effectiveness of predictive maintenance for centrifugal blower fans, let's consider a case study involving XIE HENG DA, a leading manufacturer of centrifugal blower fans.

XIE HENG DA implemented a predictive maintenance program for their centrifugal blower fans using advanced analytics and real-time monitoring. By continuously collecting data on fan performance, including vibration levels, temperature, and motor current, they were able to identify potential issues early on.

In one instance, the predictive maintenance system detected an abnormal increase in vibration levels in an axial cooling fan. Upon further investigation, it was discovered that the fan's impeller had become unbalanced due to wear and tear. Prompt maintenance was scheduled, and the impeller was repaired before a catastrophic failure could occur.

As a result of implementing predictive maintenance, XIE HENG DA was able to reduce unplanned downtime by 50% and lower maintenance costs by 30%. The company also experienced improved fan performance and increased overall productivity.

Predictive maintenance is revolutionizing the way centrifugal blower fan maintenance is approached. By harnessing the power of predictive analytics and real-time monitoring, businesses can proactively detect potential issues, optimize performance, and reduce costs. Continuous monitoring and early detection enable maintenance teams to address problems before they escalate, ensuring the smooth operation of centrifugal blower fans and improving overall productivity.

EN

EN

+

+

+

+

+

+