Fan engine cooling systems play a vital role in maintaining the optimal temperature of a vehicle's engine. By preventing overheating, these systems ensure that the engine operates efficiently and avoids potential damages. In this guide, we will explore the components of fan engine cooling systems, the working principles behind advancements in this field, and the latest advancements in fan engine cooling technology.

Components of Fan Engine Cooling Systems

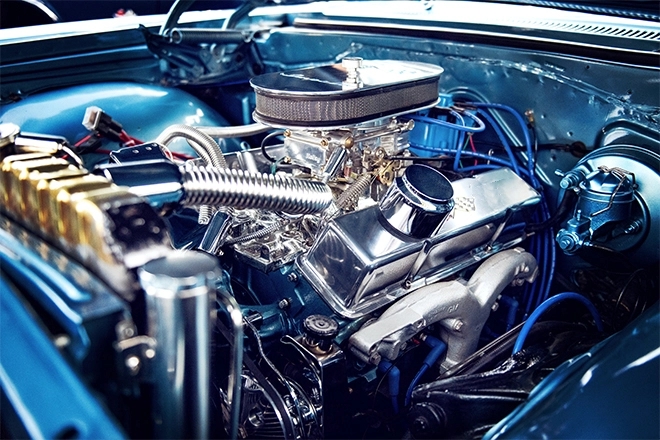

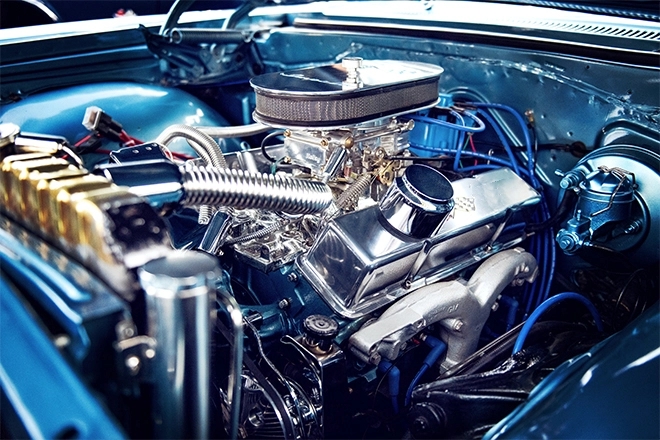

Fan engine cooling systems consist of several key components that work together to cool the engine. These components include the radiator, coolant, water pump, thermostat, and, of course, the fan. The radiator is responsible for dissipating heat from the coolant, while the coolant absorbs heat generated by the engine and carries it to the radiator. The water pump circulates the coolant, ensuring a constant flow to regulate the engine's temperature. The thermostat helps maintain the engine temperature within the desired range, allowing the fan to kick in when needed.

Working Principles of Advancements in Fan Engine Cooling

Advancements in fan engine cooling have greatly improved the efficiency and effectiveness of these systems. One such advancement is the use of electronic control units (ECUs) that monitor and regulate the engine temperature. ECUs can adjust fan speed based on real-time temperature data, ensuring that the fan operates at the optimal speed to cool the engine. This intelligent control system has significantly enhanced the cooling capacity and reduced energy consumption.

Another working principle behind advancements in fan engine cooling is the use of variable fan speeds. Traditional fan systems operated at a constant speed, which was not the most efficient approach. With the introduction of variable fan speed technology, fans can now adjust their speed based on the engine's cooling needs. This ensures that the fan operates at the necessary speed, saving energy and minimizing noise levels.

Advancements in Fan Engine Cooling

Advancements in fan engine cooling technology have led to various improvements in recent years. One notable advancement is the introduction of electric fans. Unlike traditional belt-driven fans, electric fans are directly powered by the vehicle's electrical system. This allows for better control and regulation of fan speed, resulting in more efficient cooling and reduced power loss.

Furthermore, the integration of airflow control devices has significantly enhanced the cooling performance of automotive cooling fan systems. These devices, such as air baffles and fan shrouds, help direct the airflow through the radiator, maximizing its cooling efficiency. By ensuring that the air passes through the entire radiator instead of bypassing it, these devices improve the overall cooling capacity and effectiveness of the system.

Recent advancements in materials and design have also contributed to the improvement of fan engine cooling systems. Lightweight materials, such as aluminum, are now used in the construction of radiators and fan blades. These materials not only reduce the weight of the system but also enhance its heat dissipation capabilities. Additionally, streamlined designs of fans and radiators further improve the airflow, resulting in better cooling performance.

Fan engine cooling systems are essential for maintaining the optimal temperature of a vehicle's engine, thereby ensuring its efficiency and longevity. Understanding the components and working principles of these systems is crucial for proper maintenance and troubleshooting. Advancements in fan engine cooling, such as the use of ECUs, variable fan speeds, electric fans, airflow control devices, and improved materials and designs, have greatly enhanced their cooling capacity and efficiency. By embracing these advancements, vehicle owners can enjoy improved engine performance and reliability.

EN

EN

+

+

+

+

+

+