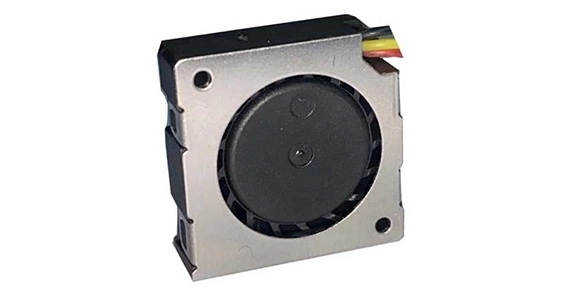

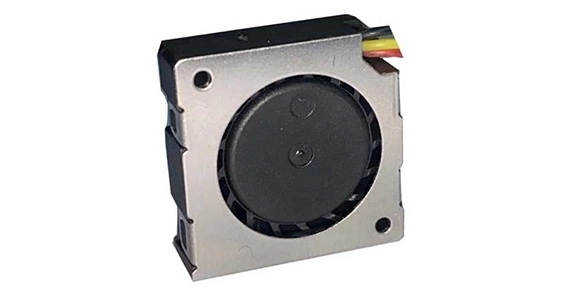

DC blower fans are an essential component in various industries and applications, including electronics cooling, HVAC systems, and automotive ventilation. These fans work by circulating air through a rotor, which is driven by an electric motor. However, one often overlooked aspect of DC blower fans is the importance of bearing types.

The Basics of Bearing Types in DC Blower Fan

Bearing types play a crucial role in the performance and longevity of DC blower fans. The most commonly used bearing types in these fans are ball bearings and sleeve bearings. Ball bearings consist of small metal balls that reduce friction and allow for smooth rotation. On the other hand, sleeve bearings are made of a sleeve of oil-impregnated bronze, which serves as a lubricant for the fan shaft.

How Bearing Types Impact DC Blower Fan Performance

The choice of bearing type has a significant impact on the overall performance of DC blower fan. Ball bearings are known for their low friction and high-speed capabilities, making them ideal for applications that require continuous operation or high RPM. They provide greater stability and lower noise levels compared to sleeve bearings. On the other hand, sleeve bearings are cost-effective and suitable for applications that do not demand excessive speed or continuous operation.

Bearing Types and DC Blower Fan Role in Noise Reduction

One critical aspect of axial air fan is noise reduction, especially in environments where noise contamination can be detrimental. The bearing type plays a significant role in the overall noise level generated by the fan. Ball bearings, due to their low friction properties, produce less noise during operation compared to sleeve bearings. This makes them the preferred choice for noise-sensitive applications.

DC Blower Fan: The Relationship Between Bearing Types and Fan Lifespan

The lifespan of a DC blower fan is determined, to a large extent, by the bearing type. Ball bearings, with their high durability and robustness, are designed to withstand high-speed and continuous operation. They have a longer lifespan compared to sleeve bearings, which are more prone to wear and tear over time. Choosing the appropriate bearing type ensures a longer fan lifespan, reducing the need for frequent replacements and maintenance.

In conclusion, bearing types play a crucial role in the performance, noise reduction capabilities, and lifespan of DC blower fans. The choice between ball bearings and sleeve bearings depends on the specific application requirements. Ball bearings are recommended for applications that demand high-speed, continuous operation, and low noise levels, while sleeve bearings are suitable for less demanding applications where cost-effectiveness is a priority. Understanding the importance of bearing types allows for informed decision-making and better performance of DC blower fans.

EN

EN

+

+

+

+

+

+