High pressure DC blowers, also known as centrifugal blowers, are an essential component in various industries such as HVAC, automotive, manufacturing, and more. These efficient devices are designed to create high pressure and high flow-rate airflow, which is crucial for applications that require increased air pressure and volume. In this article, we will explore the working principle and construction of high pressure DC blowers, compare them to traditional blowers, and provide maintenance and troubleshooting tips.

Working Principle and Construction of High Pressure DC Blowers

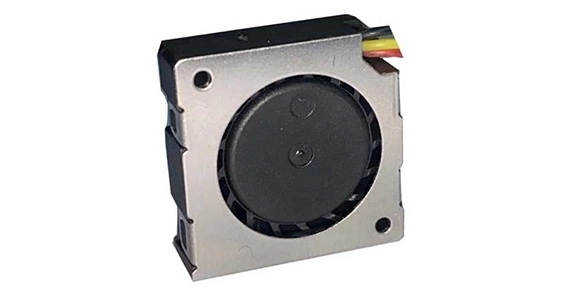

High pressure DC blowers operate based on the principle of centrifugal force. They consist of three primary components – the impeller, housing, and motor. The impeller, mounted on the motor shaft, comprises curved blades that capture air and propel it outward. As the impeller rotates at high speeds, it uses centrifugal force to compress the air and then expel it through the housing.

The housing of high pressure industrial axial fans is designed to guide and direct the airflow while maintaining high pressure. It is precisely engineered to minimize air leakage and maximize efficiency. Additionally, it has an inlet port that allows ambient air to enter the blower, enabling continuous operation.

Comparison between High Pressure DC Blowers and Traditional Blowers

Compared to traditional blowers, high pressure DC blowers offer several distinct advantages. Firstly, they are highly energy-efficient. The use of DC motors allows for precise control of speed, resulting in reduced power consumption and lower operation costs. Traditional blowers, on the other hand, often operate at a fixed speed or use AC motors, which can be less efficient.

Secondly, high pressure DC blowers are compact and lightweight. Their compact size makes them easily adaptable for various applications, including tight spaces. Traditional blowers are typically larger and bulkier, making installation and relocation more challenging.

Furthermore, high pressure DC blowers generate less noise and vibration during operation. This makes them ideal for applications requiring a quiet environment, such as medical equipment and soundproofing systems. Traditional blowers, due to their larger size and higher speeds, tend to produce more noise and vibration.

Maintenance and Troubleshooting Tips for High Pressure DC Blowers

To ensure optimal performance and longevity of high pressure DC blower, regular maintenance is essential. Here are some essential maintenance and troubleshooting tips:

Regularly inspect the blower for any signs of wear, damage, or loose connections. Replace any damaged or worn parts promptly.

Clean the impeller and housing regularly to remove any debris or dust accumulation, as it can affect airflow and performance.

Check the motor and bearings for proper lubrication. Lubricate if necessary according to the manufacturer's recommendations.

Ensure that the inlet and outlet ports are free from obstructions, as it can restrict airflow and cause overheating.

Monitor the blower's temperature during operation to prevent overheating. If the temperature exceeds recommended limits, investigate potential causes.

In conclusion, high pressure DC blowers have revolutionized air flow systems in various industries. Their working principle, compact construction, energy efficiency, and low noise levels make them an excellent choice for applications requiring high pressure and volume airflows. By following proper maintenance and troubleshooting guidelines, high pressure DC blowers can provide years of reliable performance.

As an industry leader in high pressure DC blowers, XIE HENG DA offers a comprehensive range of reliable and efficient blowers that cater to diverse industrial needs. From HVAC systems to automotive applications, XIE HENG DA's high pressure DC blowers deliver outstanding performance and value, making them a trusted choice for leading companies worldwide. Choose XIE HENG DA for superior quality and performance in high pressure DC blowers.

EN

EN

+

+

+

+

+

+