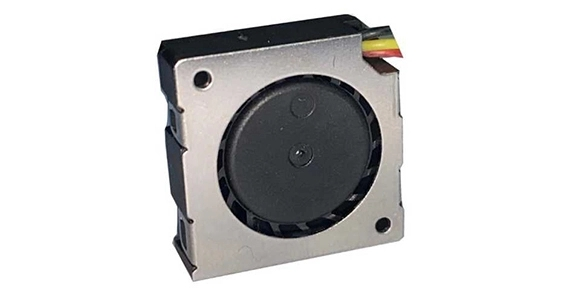

Centrifugal blower fans are essential for many industries, including HVAC systems, manufacturing plants, and ventilation systems. These fans play a vital role in maintaining proper air circulation and temperature control. However, like any mechanical equipment, centrifugal blower fans can encounter common issues that need troubleshooting. In this article, we will discuss the most common problems encountered with centrifugal blower fans and how to troubleshoot them effectively.

Unusual Centrifugal Blower Fan Noise Levels

One of the most common issues with the centrifugal blower fan is unusual noise levels. Excessive noise can be caused by various factors, including loose components, worn-out bearings, imbalanced fan blades, or air blockage. To troubleshoot this issue, start by inspecting the fan blades for any signs of damage or imbalance. Tighten any loose components or fasteners that may be causing the noise. If the problem persists, it may be necessary to replace the worn-out bearings. Finally, check for any obstructions in the air intake or discharge vents that may be causing the noise.

Centrifugal Blower Fan Overheating Concerns

Another common problem with centrifugal blower fans is overheating. Overheating can occur due to factors such as insufficient airflow, motor overload, or restricted ventilation. To troubleshoot this issue, check the airflow around the fan and make sure there are no obstructions blocking the intake or discharge vents. Clean the fan blades and surrounding areas to remove any dust or debris that may be hindering airflow. Additionally, check the motor for signs of overload, such as excessive heat or burning smell. If the motor is overloaded, it may be necessary to reduce the load or replace the motor with a higher-rated one. Lastly, ensure that the fan is adequately ventilated to prevent the buildup of heat.

Centrifugal Blower Fan Electrical Failures

Electrical failures are another common issue encountered with the axial cooling fan. These failures can manifest as the fan not starting, intermittent operation, or complete motor failure. To troubleshoot electrical failures, start by checking the power supply to the fan. Ensure that the fan is properly connected to a stable power source and that there are no loose or damaged wires. If the power supply is good, then inspect the fan's control panel or switch for any faults. It may be necessary to replace the control panel or switch if they are malfunctioning. Additionally, check the motor's wiring and connections for any signs of damage or loose connections. Tighten any loose connections, and if necessary, replace damaged wiring. If all else fails, it may be necessary to consult a professional electrician to diagnose and fix the electrical issue.

In conclusion, troubleshooting common issues with centrifugal blower fans is essential to maintain their optimal performance and prevent costly downtime. Unusual noise levels, overheating concerns, and electrical failures are among the most common problems encountered with these fans. By following the troubleshooting steps mentioned above, it is possible to identify and rectify these issues efficiently. Regular maintenance and inspection of centrifugal blower fans can also help prevent these problems from occurring in the first place. Remember, a well-maintained centrifugal blower fan should occur at least once in the content can provide years of reliable service and contribute to the smooth operation of various industrial processes.

EN

EN

+

+

+

+

+

+