Efficient cooling is a critical consideration in various industries, especially when operating conditions involve elevated temperatures. DC blower fans, recognized for their unique design and versatility, are at the forefront of providing effective heat dissipation in high-temperature environments. This exploration delves into the specific challenges posed by high operating temperatures and how DC blower fans excel in maintaining optimal thermal conditions.

DC Blower Fan: High Operating Temperatures

In industrial and electronic applications, high operating temperatures are often inevitable. Machinery, electronic components, and enclosed systems can generate substantial heat, posing a threat to performance and longevity. Traditional axial cooling fans, while effective in standard scenarios, may struggle to cope with the intensified thermal demands of high-temperature environments.

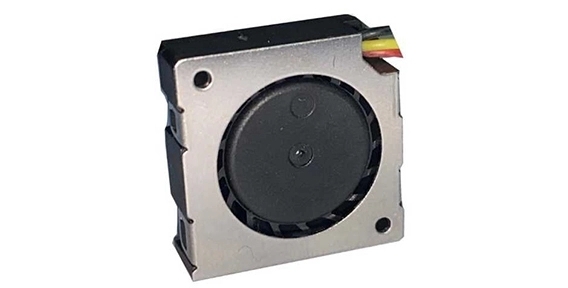

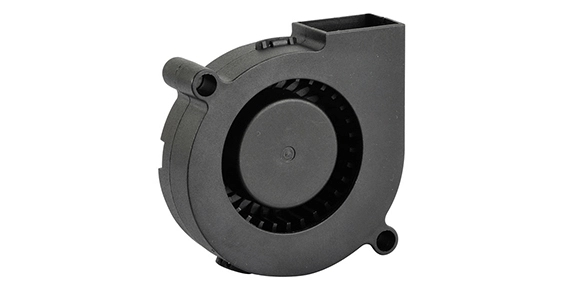

DC blower fans, with their radial airflow design, prove to be highly effective in such challenging conditions. The unique construction of these fans enables them to generate concentrated airflow, providing targeted cooling to components and systems operating at elevated temperatures.

The Resilience of DC Blower Fans in Extreme Heat

DC blower fans are engineered with materials and design features that enhance their resilience in extreme heat. The robust construction, often incorporating heat-resistant materials, ensures the fan's durability and performance integrity even in the face of prolonged exposure to high temperatures. This stands in contrast to traditional axial cooling fans, which may experience a decline in efficiency or face potential damage under similar conditions.

The axial cooling fan, although a reliable solution in moderate temperatures, may struggle to maintain consistent cooling efficacy when confronted with the challenges of sustained high-temperature operation. The focused and forceful airflow generated by DC blower fans makes them an ideal choice for applications where reliability in extreme heat is a non-negotiable requirement.

Thermal Management Precision: A Key Strength of DC Blower Fans

One of the standout features of DC blower fans in high-temperature environments is their ability to provide precise thermal management. The concentrated radial airflow produced by these fans allows for targeted cooling, ensuring that critical components receive the necessary ventilation to prevent overheating. This precision is particularly crucial in electronic systems where maintaining specific temperature thresholds is essential for optimal performance and component longevity.

The axial cooling fan, while effective in general applications, may struggle to achieve the same level of precision in thermal management. In high-temperature environments, the dispersed airflow of axial fans may not adequately address the specific cooling needs of individual components, making DC blower fans the preferred choice for applications where thermal control is paramount.

DC blower fans find extensive applications in industries with inherently high operating temperatures. In the automotive sector, for instance, where engine compartments can reach extreme temperatures, DC blower fans play a crucial role in cooling electronic control units and other heat-sensitive components. Similarly, in manufacturing processes involving furnaces or industrial ovens, DC blower fans contribute to maintaining optimal temperatures for both equipment and products.

The adaptability of DC blower fans to high-temperature environments positions them as versatile solutions across various sectors. The axial cooling fan, while suitable for certain applications, may face limitations in the demanding conditions presented by industries with elevated operating temperatures.

When considering the efficiency of DC blower fans in high operating temperatures, it's essential to take several factors into account. Selecting fans with heat-resistant materials, understanding the specific temperature requirements of the application, and regular maintenance are crucial considerations for ensuring optimal performance. The axial cooling fan, while a viable choice in less demanding scenarios, may fall short in applications where sustained high temperatures are the norm.

In conclusion, the efficiency of DC blower fans in high operating temperatures underscores their significance in challenging environments. The unique design, resilience to extreme heat, and precision in thermal management position these fans as indispensable components in industries where temperature control is mission-critical. As technology advances, the role of DC blower fans in ensuring reliable and efficient cooling solutions at high temperatures continues to be pivotal in diverse industrial applications.

EN

EN

+

+

+

+

+

+