In industrial settings, the need for powerful and efficient air blowers is crucial. These blowers are used for various applications, such as pneumatic conveying, dust collection, ventilation, and drying. Among the different types of blowers available, the dc air blower has gained popularity due to its unique design and advantages over other blowers. Let's take a closer look at the working principle and design of the dc air blower, its advantages compared to other types of blowers, as well as its environmental impact and sustainability considerations.

The working principle and design of dc air blowers

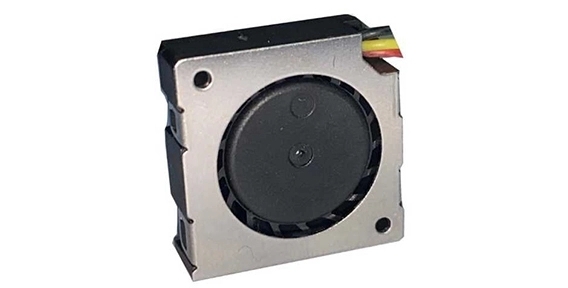

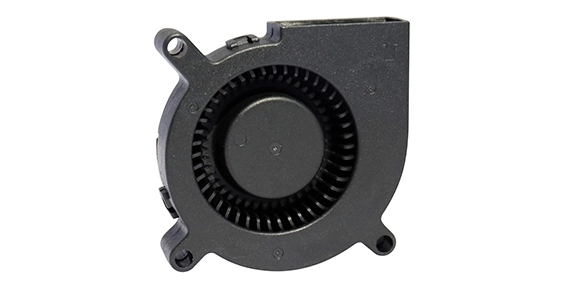

DC air blowers utilize an electric motor to generate high-pressure air. The motor is powered by direct current (DC), which allows for precise control over the air flow and pressure. The design of the DC air blower includes a fan or impeller that rotates at high speeds, drawing in air and compressing it before releasing it at high pressure. This design ensures efficient and reliable performance, making dc air blowers suitable for a wide range of industrial applications.

The advantages of dc air blowers compared to other types of blowers

One of the significant advantages of dc air blowers is their energy efficiency. The use of direct current allows for better control over power consumption, resulting in lower energy costs. Unlike other types of blowers, dc air blowers can be adjusted to deliver the required air pressure and flow rate accurately, minimizing any energy wastage. This efficiency not only saves money but also reduces the carbon footprint of industrial processes.

Furthermore, dc air blowers are known for their compact size and lightweight design. This makes them easy to install and transport, saving valuable space in industrial settings. The compact design also enables the integration of axial cooling fan into existing systems without significant modifications. Additionally, the lightweight nature of these blowers reduces the strain on supporting structures, enhancing their durability and longevity.

Another advantage of dc air blowers is their quiet operation. Noise pollution is a common concern in industrial environments, and traditional blowers can contribute to this problem. However, DC air blowers operate with minimal noise, making them ideal for applications where a quiet working environment is essential. The reduced noise levels not only improve the overall working conditions but also comply with environmental regulations and standards.

Environmental impact and sustainability considerations of dc air blowers

Sustainability is a critical factor in today's industrial processes. One of the ways dc air blowers contribute to sustainability is through their energy efficiency, as mentioned earlier. By optimizing power consumption, these blowers help reduce greenhouse gas emissions and conserve natural resources. Additionally, the compact design and lightweight construction of dc air blowers result in reduced material usage during manufacturing, further minimizing their environmental impact.

Moreover, dc air blowers often feature advanced filtration systems that remove contaminants from the air, ensuring clean and healthy working environments. This not only protects employees' health but also prevents the release of harmful substances into the atmosphere. The use of dc air blowers can, therefore, help industrial facilities comply with environmental regulations and improve their sustainability credentials.

In conclusion, dc air blowers offer significant advantages over other types of blowers in industrial settings. Their energy efficiency, compact design, quiet operation, and environmental sustainability make them an excellent choice for various industrial applications. With the continuous advancements in technology and increasing focus on sustainability, dc air blowers are unlocking the power to facilitate efficient and environmentally friendly industrial processes.

EN

EN

+

+

+

+

+

+