Industrial air blowers are essential tools used in a wide range of industries for various purposes such as ventilation, cooling, and drying. Choosing the right high-pressure industrial air blower for your specific needs is crucial for ensuring optimal performance and efficiency. This article will explore the design and operation principles of air blower fans, noise reduction strategies, and emerging trends and innovations in air blower fan technology.

Design and Operation Principles of Air Blower Fan

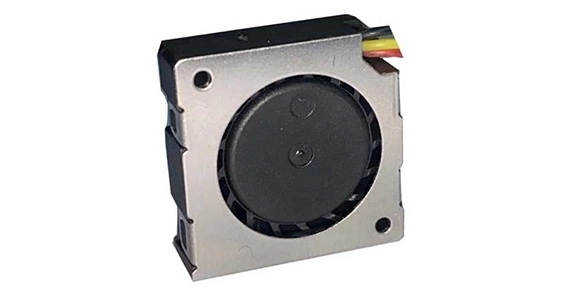

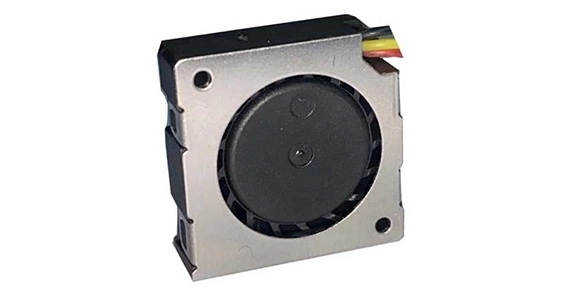

Air blower fans are designed using principles of fluid dynamics and mechanical engineering. These devices consist of an impeller or rotor, housing, and motor. The impeller is the central component responsible for creating the airflow, while the housing helps to direct and control the flow of air. The motor provides the power needed to rotate the impeller.

The impeller's design and shape play a significant role in determining the airflow and pressure generated by the air blower fan. Different impeller designs, such as forward-curved, backward-curved, and radial, offer varying levels of efficiency and performance. The selection of the impeller design depends on the specific application requirements and desired airflow characteristics.

Noise Reduction Strategies for Air Blower Fan

Air blower fans can generate considerable noise levels, which might be undesirable in certain industrial settings. To address this issue, various noise reduction strategies are employed. One commonly used approach is the incorporation of sound-absorbing materials within the blower housing or ducts. These materials help to absorb noise and reduce its propagation.

Additionally, the use of anti-vibration mounts and isolation systems can minimize vibrations that contribute to noise production. Insulation of the blower enclosure or housing can also assist in noise reduction. Regular maintenance and lubrication of the fan components can ensure smooth operation and minimize noise caused by friction or mechanical issues.

Emerging Trends and Innovations in Air Blower Fan Technology

The axial cooling fan industry has witnessed significant advancements in recent years. One emerging trend is the integration of smart technology and automation into air blower systems. This includes the use of sensors and control systems to monitor and optimize the blower's performance. Smart technology enables real-time monitoring of factors such as airflow, pressure, and temperature, allowing for proactive maintenance and energy-efficient operation.

Another innovation in air blower fan technology is the development of more efficient and sustainable designs. Manufacturers are increasingly incorporating energy-saving features, such as variable speed drives and high-efficiency motors, to reduce power consumption and operating costs. Improved aerodynamics and impeller designs contribute to higher efficiency and reduced noise levels.

Selecting the right high-pressure industrial air blower for your needs is a crucial decision that can significantly impact your operations' efficiency and productivity. Understanding the design and operation principles of air blower fans, implementing noise reduction strategies, and keeping up with emerging trends and innovations in air blower fan technology are essential factors to consider. By considering these aspects and working with reputable brands like XIE HENG DA, you can ensure optimal performance, noise reduction, and keep up with the latest advancements in air blower fan technology, contributing to the success of your industrial operations.

EN

EN

+

+

+

+

+

+