DC blower fans have become an essential component in various industries, including electronics and automotive. These fans are designed to provide efficient cooling and ventilation solutions. However, they can sometimes generate unwanted noise due to vibration. To ensure a smoother operation and minimize noise levels, it is important to understand and implement techniques for reducing vibration in DC blower fans. This article will explore some effective strategies for achieving this goal.

Understanding Vibration in DC Blower Fans

Vibration in DC blower fans can be caused by several factors. The primary source is the imbalance of the fan's rotating components. This imbalance can occur during the manufacturing process or due to wear and tear over time. Additionally, the airflow through the blades of the fan can create turbulence, leading to increased vibration and noise. Understanding and addressing these underlying causes is crucial for reducing vibration in DC blower fans.

DC Blower Fan: Achieving Mechanical Balance for Vibration Reduction

One of the key techniques for minimizing vibration in DC blower fans is achieving mechanical balance. This can be done by carefully manufacturing and assembling the fan's components. The rotor, which includes the blades and the hub, should be precisely balanced to ensure an even distribution of weight. Additionally, the motor and other internal components should be aligned correctly. By achieving mechanical balance, the vibrations caused by an imbalanced rotor can be significantly reduced, resulting in a smoother and quieter operation.

Creating a Vibration-Free Zone Around DC Blower Fans

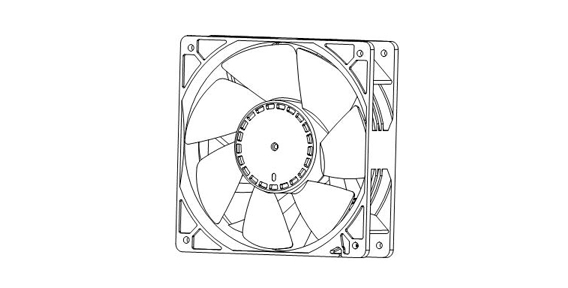

Another effective technique for reducing vibration in industrial axial fans is creating a vibration-free zone around the fan. This can be achieved by using vibration-isolating mounting systems. These systems are designed to absorb and dampen vibrations, preventing them from being transmitted to the surrounding structure. By installing the fan on a vibration-isolating mount, the vibrations caused by the fan's operation can be contained and minimized, resulting in a quieter environment.

DC Blower Fan: Streamlining Blades for Reduced Turbulence and Vibrations

The design of the blades plays a significant role in the generation of turbulence and vibrations in DC blower fans. By streamlining the blades, manufacturers can reduce turbulence and improve the fan's overall efficiency. This can be achieved by optimizing the blade's shape and angle to ensure a smooth airflow. Additionally, using materials with low friction coefficients can help reduce turbulence and vibrations. By incorporating these design considerations, DC blower fans can operate more quietly and efficiently.

In conclusion, reducing vibration in DC blower fans is essential for achieving quieter and more efficient operation. Techniques such as achieving mechanical balance, creating a vibration-free zone, and streamlining the blades can greatly contribute to minimizing vibrations and unwanted noise. By implementing these strategies, industries can ensure that their DC blower fans provide optimal performance while maintaining a quieter working environment. With continuous advancements and research in this field, manufacturers like Xie Heng Da are constantly striving to improve the design and performance of DC blower fans, ultimately benefiting various industries that rely on these cooling and ventilation solutions.

EN

EN

+

+

+

+

+

+