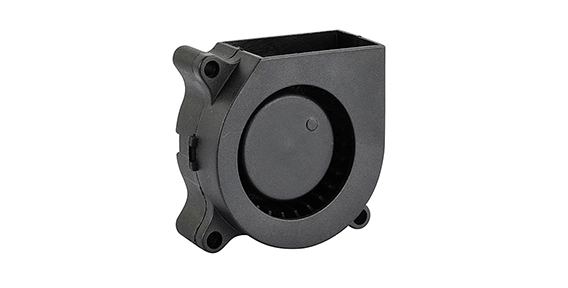

Centrifugal blower fans play a crucial role in various industrial applications. They are widely used in HVAC systems, manufacturing processes, and ventilation systems to improve air quality, control temperature, and remove moisture or fumes from the environment. When selecting a centrifugal blower fan for an industrial setting, there are several key criteria to consider. This article will discuss the selection criteria for industrial centrifugal blower fans, focusing on material compatibility and environmental conditions, size and space constraints, as well as noise levels and occupational safety.

Centrifugal Blower Fan: Material Compatibility and Environmental Conditions

One of the primary considerations when selecting a centrifugal blower fan is its compatibility with the materials present in the environment. Different industries handle various substances, including corrosive gases, chemicals, or abrasive particles. It is crucial to choose a fan constructed with materials that can withstand the corrosive or abrasive nature of the environment. Stainless steel or fiberglass reinforced plastic (FRP) are often used for their resistance to corrosion and durability.

Environmental conditions, such as temperature and humidity, also need to be taken into account. Some industries, like chemical manufacturing or steel production, operate in high-temperature environments. In such cases, the fan should be able to withstand these extreme temperatures and continue performing efficiently. Additionally, fans used in industries with high levels of moisture or humidity should be resistant to rust or degradation.

Centrifugal Blower Fan: Size and Space Constraints

Another important factor to consider is the size and space available for the installation of the axial cooling fan. Industrial settings vary in terms of space availability, with some having ample room for large fans, while others have limited space. It is essential to choose a fan that fits within the available space and can be easily installed.

The size of the fan also impacts its performance. The air volume and pressure generated by the fan are directly related to its size. It is essential to select a centrifugal blower fan that can provide the required airflow and pressure to meet the specific industry needs. A fan too small for the application may not create sufficient air movement, while a fan that is too large may consume excessive energy or create unnecessary noise.

Centrifugal Blower Fan: Noise Levels and Occupational Safety

Noise levels generated by centrifugal blower fans can be a significant consideration in industrial settings. High noise levels not only affect the comfort and productivity of the workforce but can also pose a risk to workers' hearing health. Therefore, it is crucial to choose a fan that operates quietly and meets the noise regulations set by relevant authorities.

Occupational safety is another critical aspect when selecting a centrifugal blower fan. Industries dealing with hazardous substances, such as chemicals or fumes, need fans equipped with safety features like spark-resistant construction, explosion-proof motors, or self-cleaning capabilities. These features minimize the risk of accidents or fires, ensuring the safety of the workers and the facility.

In conclusion, selecting an industrial centrifugal blower fan requires careful consideration of various criteria. Material compatibility with the environment, including resistance to corrosion and high-temperature conditions, is crucial. Size and space constraints should be considered to ensure proper installation and optimal performance. Noise levels should be minimized to safeguard workers' hearing health, while safety features are necessary for industries dealing with hazardous substances. By evaluating these criteria, industrial facilities can choose the most suitable centrifugal blower fan for their specific needs, ensuring efficiency, reliability, and the safety of their operations.

EN

EN

+

+

+

+

+

+