Achieving Optimal Noise Reduction with Acoustic Enclosures in Centrifugal Blower Fan Systems

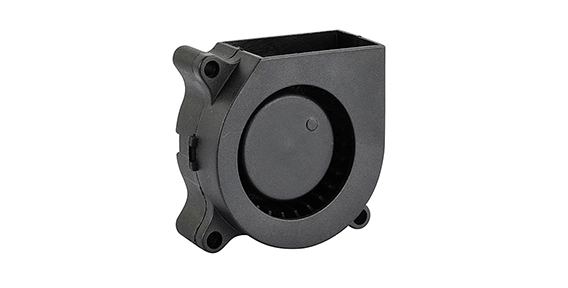

Centrifugal blower fans are widely used in various industries, including HVAC systems, manufacturing processes, and power plants. These powerful fans play a crucial role in ventilation and air circulation. However, one common drawback of centrifugal blower fans is the noise they generate. The noise produced by these fans can be disruptive to workers, affect productivity, and even pose health risks. To address this issue, many companies are turning to acoustic enclosures to achieve optimal noise reduction in centrifugal blower fan systems.

Acoustic enclosures are specially designed structures that envelop the centrifugal blower fan to minimize noise emissions. These enclosures are constructed using high-quality sound-absorbing materials that effectively absorb and reduce noise levels. By installing an acoustic enclosure around the centrifugal blower fan, the noise generated by the fan is contained within the enclosure, preventing it from spreading to the surrounding environment.

How Acoustic Enclosures Enhance Centrifugal Blower Fan Performance

In addition to noise reduction, acoustic enclosures also enhance the performance of centrifugal blower fans. The enclosure acts as a barrier that prevents external factors, such as dust, dirt, and debris, from entering the fan system. This helps to maintain the cleanliness of the fan's components, leading to improved efficiency and longevity.

Furthermore, acoustic enclosures are designed to provide proper ventilation and air circulation within the enclosure. This ensures that the fan receives an adequate supply of fresh air, preventing overheating and ensuring optimal performance. The enclosure is also equipped with openings and vents to allow for the release of exhaust air, maintaining a balanced airflow.

Choosing the Right Components for Effective Acoustic Enclosures in Centrifugal Blower Fan Installations

When selecting components for acoustic enclosures, it is important to consider the specific requirements of the axial cooling fan system. Each system may have unique characteristics that affect the design and configuration of the enclosure. Key components to consider include:

Sound-Absorbing Materials: The choice of sound-absorbing materials plays a crucial role in the effectiveness of the enclosure. Materials such as acoustic foam, mineral wool, or specialized sound-absorbing panels should be considered. These materials absorb and dampen sound waves, reducing noise levels significantly.

Structural Design: The enclosure should be well-designed to ensure proper fit and functionality. It should be sturdy, durable, and resistant to vibrations. The design should also allow for easy access to the fan system for maintenance and repairs.

Ventilation System: An effective ventilation system is essential to prevent the buildup of heat and maintain optimal airflow. The enclosure should be equipped with strategic openings, vents, and ducts to allow for the intake and exhaust of air. The choice of ventilation components should be based on the specific requirements of the fan system.

Airflow Management: Proper airflow management within the enclosure is essential for efficient fan performance. The enclosure should be designed to minimize air turbulence and ensure a steady supply of air to the fan system. This can be achieved through the use of baffles, diffusers, or other airflow control devices.

Acoustic enclosures provide an effective solution for reducing noise levels in centrifugal blower fan systems. By selecting the right components and designing the enclosure to meet specific requirements, optimal noise reduction can be achieved, enhancing both worker comfort and fan performance. With the use of high-quality sound-absorbing materials, sturdy construction, and proper airflow management, acoustic enclosures can significantly improve the operating conditions of centrifugal blower fan installations.

EN

EN

+

+

+

+

+

+