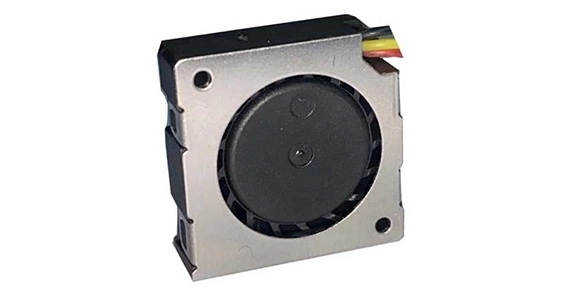

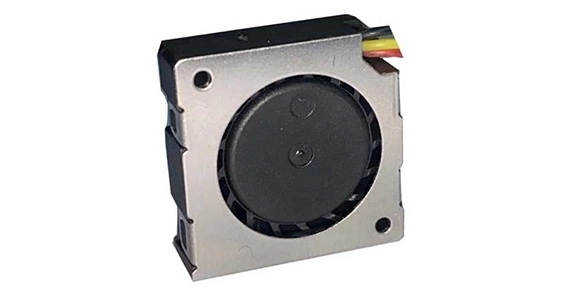

DC blower fans are crucial components in various industries and applications, used for ventilation, cooling, and airflow regulation. These fans play a vital role in maintaining optimal working conditions for machinery and equipment. To ensure the longevity and efficiency of these fans, preventive maintenance is essential. This article will discuss the components requiring regular inspection in DC blower fans, the impact of dust and debris on their performance, ways to extend the life of their bearings, and implementing smart solutions for proactive maintenance.

DC Blower Fan's Components Requiring Regular Inspection

Regular inspection of a DC blower fan's components is crucial to identify any signs of wear and tear, excessive vibration, or mechanical issues. The key components that require attention include the motor, fan blades, housing, and electrical connections.

The motor is the heart of the DC blower fan, and any malfunctioning can lead to decreased performance or complete breakdown. Regularly inspect the motor for any signs of overheating, unusual noise, or loose connections. It is essential to check the fan blades for dust accumulation, corrosion, or damage, as these factors can affect airflow efficiency.

Moreover, inspect the housing of the blower fan for any cracks, damage, or loose mounts. Ensure that electrical connections are secure and free from corrosion or loose wiring, as they can lead to electrical failures or short circuits.

The Impact of Dust and Debris on DC Blower Fan Performance

Dust and debris can significantly impact the performance of a DC blower fan. These particles can accumulate on the fan blades, housing, and motor, reducing their efficiency and increasing the risk of breakdown. Dust buildup can cause imbalance in the fan blades, leading to excessive vibration and noise.

Regularly clean the blades, housing, and other components to prevent the accumulation of dust and debris. Use a soft brush or compressed air to remove stubborn particles. Additionally, consider installing filters or screens to prevent large debris from entering the blower fan.

DC Blower Fan: Extending the Life of Bearings

The bearings in a DC blower fan are critical for smooth operation and reduced noise. Proper maintenance of these bearings can significantly extend their lifespan. Lubrication is crucial for reducing friction and preventing premature wear. Regularly check the bearings for signs of lubrication deficiency or excessive wear.

Clean the bearings and apply a suitable lubricant as per the manufacturer's guidelines. Ensure that the lubricant used is compatible with the fan's operating conditions. Additionally, monitor the bearing temperature regularly as high temperatures may indicate a lubrication issue or excessive load.

Implementing Smart Solutions for DC Blower Fan's Proactive Maintenance

Advancements in technology have provided smart solutions for proactive maintenance of industrial axial flow fan. Internet of Things (IoT) enabled sensors and predictive analytics can help monitor the performance of the fan and identify potential issues before they become significant problems.

By installing sensors, operators can monitor parameters such as temperature, vibration, and power consumption in real-time. This data can be analyzed to detect anomalies or deviations from normal operating conditions, enabling proactive maintenance actions to be taken.

Additionally, predictive analytics can help identify trends and patterns in fan performance, allowing for the optimization of maintenance schedules and the prevention of unexpected breakdowns. By implementing these smart solutions, operators can minimize downtime, optimize fan performance, and reduce maintenance costs.

In conclusion, preventive maintenance is crucial for the efficient and long-lasting operation of DC blower fans. Regular inspection of components, cleaning of dust and debris, proper lubrication of bearings, and implementation of smart solutions are all essential aspects of preventive maintenance. By following these practices, operators can ensure the optimal performance and longevity of their DC blower fans.

EN

EN

+

+

+

+

+

+